Built in 1888, I removed all the gas from the 4-Unit building I own and live in on 22nd Street in the Mission District in San Francisco.

Why?

In the 1950's a few scientists posited that humanity was contributing to global warming. A minority view back then, today 97% agree. I also agree and believe that Global Warming is real and that I need to do something about it.

In 2015 countries from around the world modified the original Kyoto protocol with a Climate Treaty, aimed at reducing global warming, and committed to limiting world temperature increases to 2 degrees centigrade, while concurrently working towards a lower target of 1.5 degrees centigrade.

What and how?

To help reach these targets I'm committed to reducing my own energy consumption where possible, walking or bike riding when possible, and where I can't, use those technologies currently available to help me lower my carbon footprint for myself and others, which includes the 4 unit building I own and live in, with installing: Solar; EV auto and charging; heat pump water heaters; induction cooktops; heat pump heat; insulation and building seal; dual pane windows; and LED lighting.

Currently I see myself as a sort of guienea pig going through the ups and downs of the conversion gas to electric conversion process, including the bureaucratic approval process, as well as the challenging rebate process, to assist all of us committed to installing the above mentioned equipment and appliances.

Rebates?

As far as the rebates that mitigate the costs of making this conversion, as I understand it, the Federal Government provides income tax rebates, and the State cash rebates, via the CPUC, having San Diego Gas & Electric, Southern California Edison, and PG&E entering into contracts with non-profits who qualify those applying for the rebates, verify that has been completed, and then release the funds.

So here we go!

I had the five PG&E gas meters in my building, for the building lighting, as well as the existing four units, removed. Adios gas. Do I now call my utility supplier Pacific No Gas & Electric?

Gas meters removed and the access to the is line locked.

After this I contacted PG&E and they made a permanent gas removal from my building to the gas line by severing the supply line in the street.

My electrician installed a larger Electric Service, from 100 to 200 AMPS

Just prior to the gas removal, I had the existing electrical service upgraded from 100 AMPS to 200AMPS, to meet the additional needs of a fully electrical building.

One note, I am part of a group of folks that are trying to stay within 100AMPS to supply all our electrical needs, rather than upgrading my main service to 200AMPS.

Currently each unit in my building has the same capacity for 100AMPS.

Prior to this I did load calcs, that showed my use could be kept under 100AMPS.

Now, 3 months after install, I have monitored the load on my unit, and may maximum load to date has been 50% under maximum load capacity.

It took 6 months from my service upgrade application, until PG&E made the final electrical connection. Its important to get started early on this.

Here the PG&E linesman connects the three new lines, two hot 120V lines, and one neutral, at the weatherhead of my main electrical service drop.

This is how every house, and apartment building gets electrical power, from the power pole at the street, to your service drop at the weatherhead.

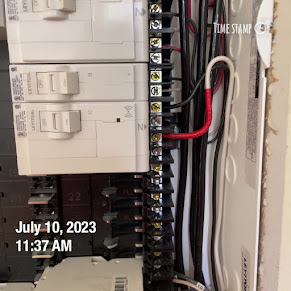

Installed new Disconnects from the Smart Meters to the new Sub-Panels

I have 5 PG&E smart meters, each with its own shut off or disconnect. The disconnects, at 40AMPS, each had to be upgraded to 80 or 100 AMPS, with new larger wiring from the meter head, to the upgraded disconnects, that shuts off the power when needed.

In this photo, in the lower right corner is the main disconnect, for the main service delivery from the street at 200AMPS, with the five meters above, and above those the disconnect for each unit, upgrade to 80 or 100AMPS. To the upper left you see the inverter for my solar panels, with DC electricity that comes from my roof.

From there I ran new wiring from the disconnects to power the new smart Circuits in all new Sub-Panels

Old sub panel on left, new Leviton Panel with Smart Breakers on the right.

From each of those 5 meter heads, then to the a Disconnects, and then to each of the 5 sub-panels, new wires were fed to each unit. The 80 or 100AMPS feeds electricity to the sub-panels that provide power to the circuit breakers that feed all of each units electrical needs: outlets, lights, appliances, and new mechanical equipment.

Snap-in Smart Circuit Breakers

Leviton makes a Sub Panel that can receive either standard circuit breakers or smart circuit breakers, each of which click into the panel. For my units the entire panel has smart circuit breakers, in the tenants, only the new electrical appliances and mechanical equipment.

Next, replace the gas water heaters with electric Heat Pump Water Heaters

Disconnected the gas water heaters, drained out the water and removed them. Strapped the water heaters to the wall, connected each to a disconnect switch for power, installed a thermostatic valve, and then connected each to the cold water inlet that feeds the building and hot water outlet that goes to each unit.The units are of one piece, with the heat pumps on top, and the tanks below. The heat pumps create some moisture as they work, and this requires a condensate drain, in white.

Each unit is then programed to lower the temperature during peak use hours, TOU, for efficiency, keep costs down, and is a requirement for some rebates.

To remove the gas, including the residual Benzene that migrates from the cooktop round the house, I installed Induction Cooktops

At each cooktop took out the cabinet drawers to access the old BOSCH gas lines.

Removed the gas lines.

Removed the gas cooktop, and then routered out each kitchen counter for the larger drop-in opening required for the induction cooktop install.Dropped in the new induction cooktop, hard wired each to a new 240V outlet in the wall, fed by wires fished through the existing walls to new smart circuit breakers at the sub-panel

Heat Pump Split Systems

THIS IS THE HARDEST TO CONVERT TO ALL ELECTRIC!!!!

Easy part? Removing the old existing Marley direct current Electric Baseboard Heaters. Opened up the junction box that connects to each unit to electricity, cut the wires, capped them, and installed a new wall flush j-box face plate.

There's a light well on each side of the building, where we hung the outdoor part of the Split System, the fan/condenser units. By this time I was doing all the electrical myself. I installed 240V power and a service outlet for each heat pump unit in the light wells, and disconnect for each unit.

The crew dropped the outdoor HVAC units onto mounting brackets

in the light well, and wired them to power, and ran power and refrigerant lines to the indoor units.

SO MUCH DRILLING!

If you have an existing building, much of the project work is drilling holes in existing framing to conceal the refrigerant or water lines behind the walls.

Running those lines is tough work.

Heat moves to cold, so the outdoor condenser fan units are what picks up or expels the heat via the refrigerant, compresses it, then the refrigerant lines travel through holes in the interior walls from the outdoor unit to the (3) indoor units to provide heating and cooling. Electrical needs for the indoor unit come from electrical lines from the outdoor unit, that are zip tied to the refrigerant lines.

Combination Heat Pump Water & Heat

There are many HP HVAC systems besides split systems including Air to Water. As with the Split Systems there is an outdoor Fan/Condenser, but in this case water travels to and from the unit, not refrigerant.

This system has (2) 43 gallon hot water tanks, one feeds the domestic hot water, and the other the coil, which blows air over it, and the heated air travels in a duct 9" diameter duct that runs the length of the building.

The large duct, then feeds the hot air into small 1 1/2" diameter high velocity ducts up high, to the ceiling or wall, sending warm air that mixes in with the existing.

The heat registers are small, about the size of a small

ceiling recessed can light.

That's it! Entire building is now electric.

Monitoring the system.

We've been monitoring the system for the past 3 months, and energy bills are about 1/2 of last year. We plan to continue to make improvements by increasing the water tank temperature 20 degrees, adding more insulation to create , and replacing the remaining single pane windows with dual pane.

No comments:

Post a Comment